Oratio:

No.233-3 Yangchenghu via, Xixiashu Industrial Park, Xinbei dolor, Changzhou urbem, Jiangsu provinciae

Introductio:

In mundo subtilitatis machinis, rectam methodum creandi fila eligendo pendet ad optimos eventus assequendos secundum vires, metam et altiorem cost-efficentiam. Inter methodos frequentissimos usus ad sequela conficienda sunt stamina milling et percussa. Utraque methodo dum vigent, suas quisque utilitates, limitationes et missiones optime utentes habent.

In hoc articulo, penitus in sequelam molendi et percutiendi subtilitates infundemus, explorantes cum una methodus prae ceteris potior sit, et factores tamquam proprietates materiales analyses, magnitudines, foramen profundum, et productionem voluminis.

1. Intellectus Basics of Post Milling et Tapping;

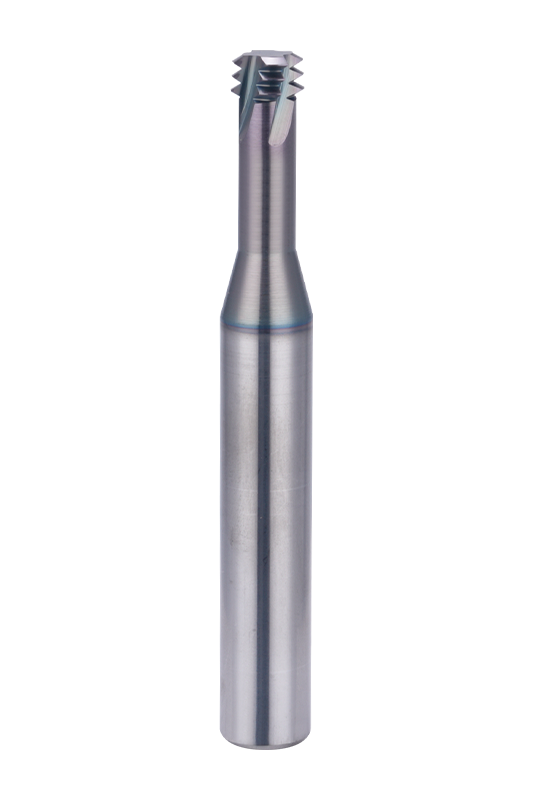

Post Milling:

Fila milling circumducitur dromonem utens involvit ut fila in foveam efficiat. Dromones per superficiem in helicum tramitem movetur, optatum stamina profile formans. Hic processus conficitur utens machinae CNC molentis, et instrumentum typice habet oras incisas multiplices quae cum materia simul confligunt.

Ictibus:

Ictibus e contra est processus in quo instrumentum percussionis (similis terebrae cum filis incisis) ad stamina interna creandum adhibita est per instrumentum intra foramen circumactum. Ictibus proprie fit utens torno vel verticali machinis centro CNC.

2. Differentiae Key:

2.1. Requisita Tooling:

Thread Milling : Molendiariam dromonem specialem requirit cum pluribus marginibus incisis, quae simul stamina dextra et sinistra utebatur creare potest.

Ictibus: Uses a single-point tool that cuts threads directly into the material, and there are different taps for different materials and thread forms.

2.2. Machina PRAEFIXUS et Versatility:

Post Milling: Offers more versatility as it can be used to create a variety of threads, including larger sizes or custom profiles, on both blind and through holes. It can also be done on a CNC mill, which is more versatile in terms of general machining operations.

Ictibus: Typically requires a dedicated tapping cycle, making it somewhat less versatile in terms of setup and customization compared to thread milling.

2.3. Post Sagaciter:

Post Milling: Typically provides a higher level of accuracy and surface finish because the cutter does not have to engage the material at the same point as a tapping tool. It's also easier to adjust parameters for thread size during the milling process.

Ictibus: Tapping may experience slight inaccuracies due to tool wear, especially in hard materials. It can also have issues like tool breakage in deeper holes or irregular threads in challenging materials.

3. Material considerationes:

3.1. Durum Materiae (exampla, Diver, Titanium);

Post Milling: Ideal for hard materials as it reduces the risk of tool breakage. Thread milling also doesn’t generate as much heat as tapping, which helps maintain tool life and quality.

Ictibus: In hard materials, tapping can be slower and more prone to tool breakage. Also, tapping deep holes in hard materials is generally not recommended because of potential tool deflection and failure.

3.2. Mollis materias (exampla, aluminium, aes);

Post Milling: Works well for soft materials but might be slower than tapping due to the multi-cutting-edge nature of the operation.

Ictibus: Faster in soft materials, as it’s a more direct process with minimal setup required.

4. Factores Influentes The:

4.1. Post magnitudinem ac profundum;

Post Milling: Works well for larger threads (above 1/2” in diameter) and deep threads. It’s especially effective for creating internal threads that are deeper than the length of a typical tap.

Ictibus: Best suited for shallow threads, generally under 1” in diameter. The deeper the thread, the more likely tapping will cause issues like tap breakage or thread deformation.

4.2. Cycle Time and Production Volume:

Post Milling: The cycle time is generally longer due to the process’s complexity, and while it can be optimized with multi-tooth cutters, it’s not as fast as tapping in many cases. However, in low-volume or custom runs, it may be the better option due to its versatility.

Ictibus: Tapping tends to be faster in high-volume production when making threads in shallow holes with a small diameter. The faster tool engagement allows quicker threading, especially for industries requiring large quantities of parts.

4.3. Chip Control:

Post Milling: Thread milling produces continuous, manageable chips, reducing the risk of chip buildup and allowing for better heat dissipation.

Ictibus: Can produce short, broken chips, which may become trapped in the hole and lead to issues like chip packing or tool clogging. Special care must be taken to ensure chip evacuation, especially in deeper holes.

5. Commoda Thread Milling:

Versatilitas: Sequela milling varietatem sequelae variam creare potest, cum staminibus non-vexillis et structuris.

Subtilitas: Accuratio superior, praesertim fila maiora vel altiora.

Instrumentum vitae: Instrumenta diutius durare ob actionem mitiores sectionem.

Non opus est Foraminibus Prae-terebratis: Filum milling a magnitudine foraminis non dependet, quod maiorem flexibilitatem in foraminis magnitudinibus concedit.

Multi- negotium Facultas: A CNC machina milling aliis operationibus adhiberi potest, ut sunt versus, EXERCITATIO, vel contour milling, quae efficientiam auget.

6. commoda Tapping:

Celeritas: Tapping processus ieiunium est, praecipue pro stamina tenuium in materiis mollibus.

Simplicitas: Copula et instrumentum inter se simplices et sumptus efficaces comparantur cum sequela milling.

Sumptibus tooling inferior: Ictibus instrumenta plerumque vilia sunt quam mola fila, quae magis oeconomice faciunt pro magno volumine, applicationes tenui-filae.

Constantia: In summo volumine productio currit, percussoque tendit ut in sequelae formatione constantior sit et facilius automate.

7. Applications aptissima Thread Milling:

Magnitudines sequelae magnae: sequela milling apta est pro maioribus filis (super 1/2") vel applicationes altae praecisionem.

Alta vel caeca perforata: Cum de profundis foraminibus agitur, linum milling melius permittit ut deflexio instrumenti et accurationis liniendae moderatio.

Materiae machinae durae: tritura milling saepe est ad methodum difficilium materiarum sicut ferrum robur altum, ferrum immaculatum, et titanium.

Formae sequelae complexae: Milling sequela facile creare profiles non vexillum vel consuetudinem sequelae, aptas ad angulum applicationum efficiens.

8. Applications aptissima Tapping:

Fila parva, vadum: Ictibus efficax est ad stamina parva et tenuia facienda in materiis mediis mollibus.

Summus Volubilis Productio: Cum opus magnum numerum partium linamentorum cito producere debes, Ictibus est saepe electio oeconomica magis.

Simplex filum Requisita: Pro directa, regulae fila, Ictibus est efficax et sumptus efficens.

conclusio:

In summa, tam mola quam mola quam percussio sua beneficia et limitationes habent. Electio inter duos modos a pluribus elementis pendet, inclusa duritie materialis, magnitudo fili, foramen profundum, volumen productionis, et filum qualitas requisita.

Stamina enim maiora, altiora et alta praecisione, stamina mills saepe est electio superior.

Minora, breviora stamina in materiis mollioribus, Ictibus remanet optio certa et velocior.